Description

Adhesive Hot Melt Aluminum Foil Polyimide PI Cable Tape attribute high working temperatures up to 250 °C, chemical resistance, high mechanical strength, impervious to weathering, and water resistance, without the low loss of electrical properties and high tensile strength. It has excellent dielectric properties and makes it highly convenient to use in difficult shapes.

Adhesive Hot Melt Aluminum Foil Polyimide PI Cable Tape, also known as Adhesive AL PI Shielding Tape. It has superior wire wrap and insulated tape for high-temperature and high-dielectric applications. Because of the excellent mechanical and dielectric properties, and good radiation resistance, the AL PI Tape is also used for Aerospace cables, Military cables and high-temperature industrial cables.

Polyimide film works as a backing material, laminating with the aluminum foil and the copper foil becomes the high working temperature EMI shielding tape. These EMI shielding tapes are good tapes for military and aerospace cables, replacing the Aluminum Foil Polyester Tape and Copper Foil Polyester Tape.

Adhesive Hot Melt Aluminum Foil Polyimide PI Cable Tape Specifications

Thickness: 25, 30, 38, 51, 54, 78 …… or customized

Width: >1mm

Material: Polyimide+Aluminum Foil

Working Temp.: – 80°C to 260°C(-112°F to 500°F)

Tensile Strength: ≥80MPA

Elongation: ≥30.0%

Color: Natural

Core size: 30mm, 50.8mm(2 inch), 76.2mm(3 inch) or customized

FEATURES

- Soft and good mechanical toughness

- Wrap the military, and aerospace wires and cables.

- Designed to meet the high working temperature cable industrial and electrical applications for insulation, EMI shielding, and wrapping

- Polyimide has amazing chemical resistance and radiation resistance properties.

MANUFACTURE & INSPECTION

LAMM produce Hot Melt Polyimide Tape following the below steps:

- Raw Material => 2. Making Film => 3. Coiling => 4. Quality Inspection => 5. Slitting customized=> 6. Coiling customized => 7. Online Quality Inspection => 8. Packing => 9. Shipping

LAMM always follow the strict quality control policy, more information, please click Quality Assuranc

Slitting / Cutting

LAMM Cable Tape Solutions has the industry’s top slitting ability and can cut any width material with a width >=1mm. Independently design and manufacture its patented slitting machinery and equipment.

Read more about Slitting Services or our Converting Services

WINDING / PACKING

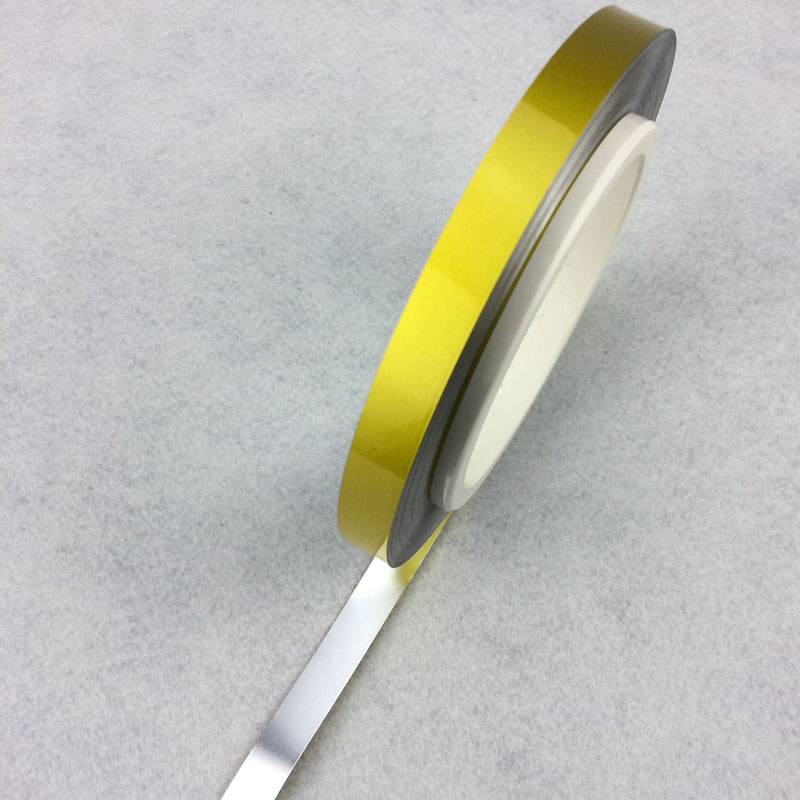

After the PI tape is slit, tape can be packed in PADS / SPOOLS. Available thickness ranges from 50μm through 508μm (0.002 through 0.020 inches), and widths ranging from 0.6mm through 100m (0.024 through 3.94 inches) or customized.

Rolls are usually set on a standard 30mm, 3 in and 6 in or customized

APPLICATIONS

- Aerospace cable tape

- Chemical Resistant Wire tape

- Chemical Resistant Cable tape

- Radiation Resistant Wire tape

- High working temperature Flat cable tape

- Military cable tape

- Applications requiring high working temperature insulation and wrapping

- Applications requiring heat resistance