Description

Cable Shielding PTFE Copper Foil Tapes, one of the foil tapes are used to shield cables. This foil tape features an extremely malleable, high tensile copper foil which is laminated with PTFE for excellent shielding and insulation. The tape is suitable for industrial and electrical applications including EMI/RFI (Electromagnetic Interference / Radio Frequency Interference) shielding. Cable Shielding PTFE Copper Foil Tapes resist failure from common sources of degradation including moisture, ultraviolet rays and many chemicals, and are commonly used for reflecting, wrapping, masking, sealing, and other applications. They are also thermally conductive for heating/cooling efficiency.

Cable Shielding PTFE Copper Foil Tapes Specifications

Thickness: 10, 12, 14, 22, 23µm …… or customized

Width: >0.6mm

Laminated method: Single side / Double side

Conductive: Conductive / Full conductive

Material: PET+CU / CU+PET+CU / PTFE+CU / CU+PTFE+CU

Working Temp.: 120°C( 248˚ F, long-term) / 200°C( 2392˚ F, short-term)

Color: Natural

Core size: 30mm, 50.8mm(2 inch), 76.2mm(3 inch) or customized

FEATURES

- Soft and good mechanical toughness

- Wrap the wires and cables.

- Designed to meet a wide variety of EMI and RFI industrial and electrical applications

- 8 µm (0.31mil) electrolytic grade copper foil backing is extremely malleable

- PTFE has amazing chemical resistance, corrosion resistance, strong acid and strong alkali resistance, water and various organic solvents resistance.

- Good thermally conductive for heating/cooling efficiency

What is PTFE?

PTFE has amazing chemical resistance, corrosion resistance, strong acid and strong alkali resistance, water and various organic solvents resistance.

PTFE has excellent thermal and electrical insulation properties.

MANUFACTURE & INSPECTION

LAMM produce PTFE Tape following the below steps:

- Raw Material => 2. Making Film => 3. Coiling => 4. Quality Inspection => 5. Laminating =>6. Quality Inspection => 7. Slitting customized=> 8. Coiling customized => 9. Online Quality Inspection => 10. Packing => 11 Shipping

LAMM always follow the strict quality control policy, more information, please click Quality Assurance

Slitting / Cutting

LAMM Cable Tape Solutions has the industry’s top slitting ability, and can cut any width material with a width >=0.6mm. Independently design and manufacture its own patented slitting machinery and equipment.

Read more about Slitting Services or our Converting Services

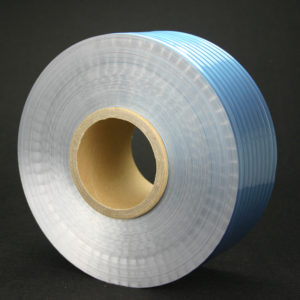

WINDING / PACKING

After the PTFE tape is slit, tape can be packed in PADS / SPOOLS. Available thickness ranging from 50μm through 508μm (0.002 through 0.020 inches), and widths ranging from 0.6mm through 100m (0.024 through 3.94 inches) or customized.

Rolls are usually set on a standard 30mm, 3 in and 6 in or customized

APPLICATIONS

- EMI and RFI shielding

- Flexible flat conductors

- Electrostatic applications

- HDMI 2.1 cable tape

- USB4 cable tape

- Auto cable (Automotive cable)

- Coaxial cable

- Aerospace cable tape

- Wires and cables for military Industry

- High-speed cable tape such as SFP series / USB series / HDMI series / Thunderbolt / Display Port etc

- MINI-SAS cable tape

- FFC cable tape

- SATA cable tape

- Applications where static discharge is a concern

- Applications requiring electrical conductivity and additional corrosion resistance