Description

Sintered PTFE Wrapping Film Tape, attributes like high elongation, impervious to weathering. It is used for wire and cable wrapping industry. It has excellent dielectric properties and more makes it highly convenient to use in difficult shapes.

What is PTFE?

PTFE has amazing chemical resistance, corrosion resistance, strong acid and strong alkali resistance, water and various organic solvents resistance.

PTFE has excellent thermal and electrical insulation properties.

PTFE applications

Sintered and Unsintered PTFE Tapes, Semi-conductive PTFE Tapes are the three main types Lamm’s design engineers use for cable and wire industry.

For manufacturers of military and commercial aircraft electronic equipment cables, Lamb engineers have designed PTFE tapes of different densities and thicknesses with excellent insulation properties. Cable manufacturers wrap Unsintered PTFE Tape from Lamm Material, around a conductor and then heat-sinter it to produce potent electric wires with integrity, rigidity and uniform insulation. Cable manufacturers also use Unsintered PTFE Tape from Lamm Material to create high-speed data cables of superlative quality and with minimal signal loss.

A) Unsintered PTFE can be used to manufacture the PTFE Insulation Tapes for cables with high temperature resistance, flame retardant and fireproof requirements, and PTFE Wrapping Film Tape.

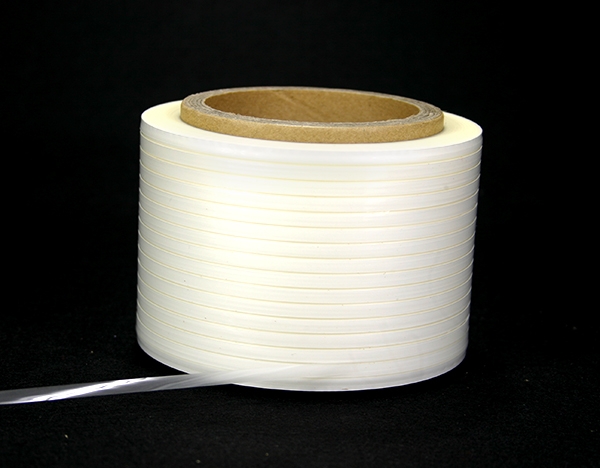

Sintered PTFE Wrapping Film Tape Specification detail:

| Density g/cm³ | Color | Width cm | Thickness μm | Tensile strength mpa | Elongation % | Tube Core Inner Diameter mm/inch |

|---|---|---|---|---|---|---|

| 2.1 | Natural color | 0.6 ~ 200 or customized | 25 / 30 / 35 / 40 / 50 / 60 / 75 / 90 / 100 / 130 / 150 / 200 etc | >=10.0 | >=20.0% | 30mm / 50.8 mm (2 inch) / 76.2 mm(3 inch) or customized |

PTFE Wrapping Film Tape can be applied to but not only the following cables:

– Flexible Wire Harness Cable,

– Fiber and Ethernet high-speed cables such as SFP / ZSFP / QSFP etc

– FFC (Flexible Printed Circuit) Cable

– Aerospace cables

– Wires and cables for military Industry

– Wires and cables for robot industry

– Industrial swing resistant cable

– Coaxial cable / micro coaxial cable etc

B) Sintered PTFE Tape can be used for cables with Sintered insulation, isolation requirements. Density range from 2.14 through 2.19 g/cm³

C) Semi-conductive PTFE Tapes are soft and good mechanical toughness. Manufacturers use it to wrap the wires and cables. And it has the ability of anti noise; restrain primary battery reaction and eliminating static electricity.

Manufacture and Inspection

Lamm produce PTFE Tape following the below steps:

- Raw Material => 2. Making Film => 3. Coiling => 4. Quality Inspection => 5 Slitting customized=> 6. Coiling customized => 7. Online Quality Inspection => 8. Packing => 9 Shipping

Lamm always follow the strict quality control policy.

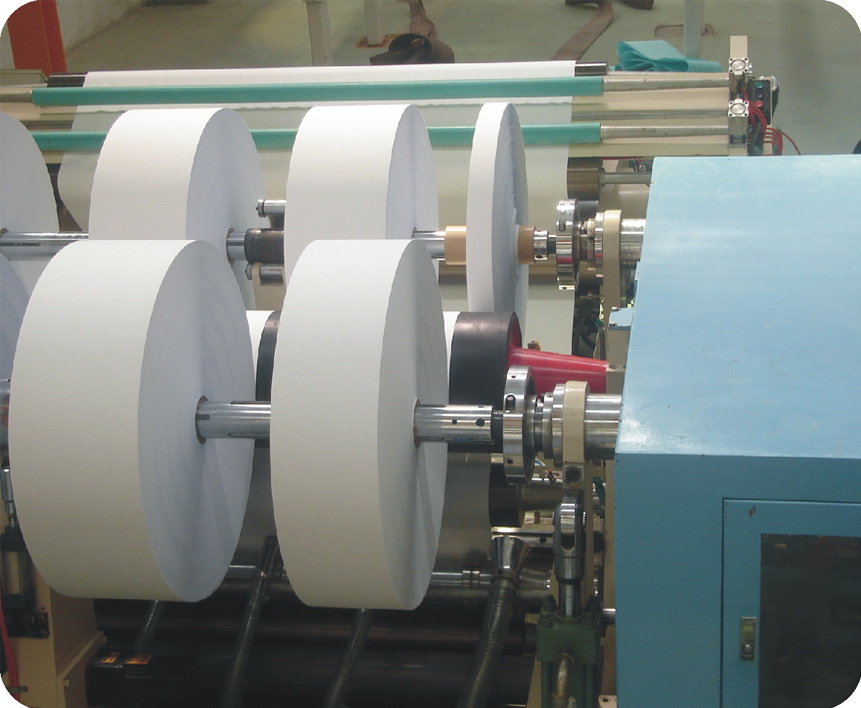

Slitting / Cutting

Lamm Material has the industry’s top slitting ability, and can cut any width material with a width >=0.3mm. Independently design and manufacture its own patented slitting machinery and equipment. There are 6 invention patents and utility model patents for equipment.

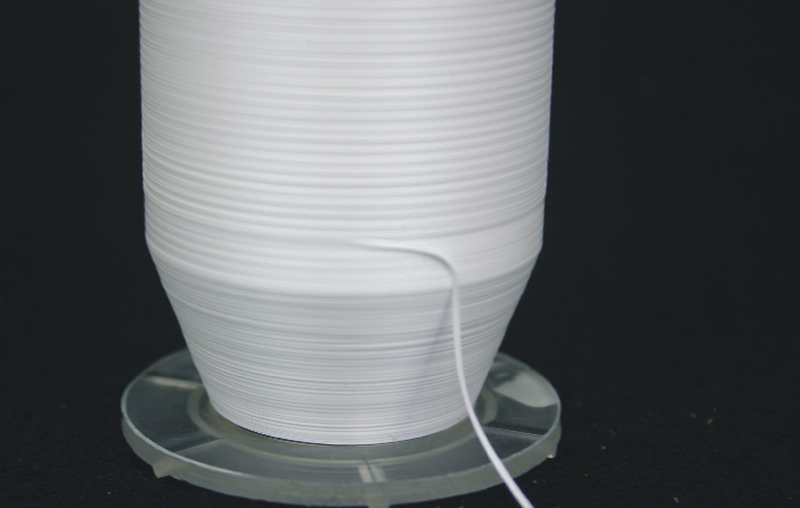

Coiling / Packing

After the PTFE tape is slit, tape can be packed in PADS / SPOOLS. Available thickness ranging from 50μm through 508μm (0.002 through 0.020 inches), and widths ranging from 0.3mm through 100m (0.012 through 3.94 inches) or customized.

Rolls are usually set on a standard 30mm, 3 in and 6 in or customized